Cube67 Hygienic Design

Easy cleanability

The food sector has particularly demanding requirements for the durability and cleanability of the components that are used in a system. The Cube67 Hygienic Design modules have been designed to fulfill all of them.

They feature a closed stainless steel housing as well as V4A (1.4404) threaded sleeves. They are designed to facilitate cleaning. With an IP69K rating, a Cube system can be used in any food zone.

This comes with great potential for cost reductions:

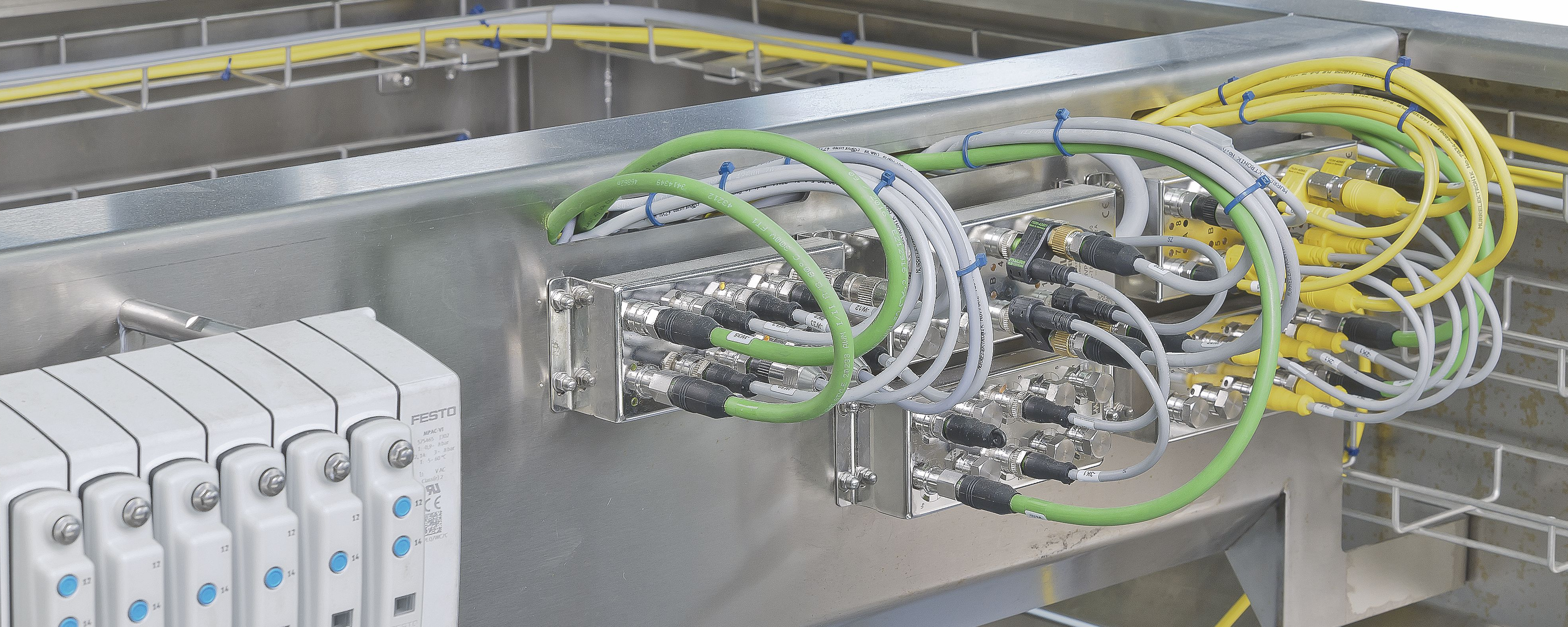

- By using Cube67 Hygienic Design modules, the particularly costly stainless steel terminal boxes used in the food sector can be phased out completely.

- Parallel wiring of individual cables over stainless steel screens in food & beverage applications is extremely complicated. The Cube system enables a direct process connection with a single system connection.

- Valve manifolds can be implemented in a cost-efficient way via the IO-Link master module.

One cable technology that connects directly to the machine

In the food industry, point-to-point wiring is particularly labor-intensive due to the high cleaning demands. Using Cube67’s one cable technology is one of the best and most effective solutions for this industry.

Explore more fieldbus solutions using the Cube system...